Snake game on 8x8 LED matrix using the STM32F4 discovery board.

In this post we will be implementing a snake game on bare metal. This means we will only use assembly and registers, without any fancy tools such as the CUBEMX :)

Parts list

- STM32F407G-DISC1 board

- 8x8 LED MATRIX with MAX7219 display driver.

- Joystick module

- Wires with female to female dupont connectors

Lets start

As a starting point we are going to take this repository which is basically a modified version of the stm32f4 assembly template by fcayci to get assembly up and running on the stm32. As I am not going to explain how to find register addresses in this tutorial, the assembly template has all the address constants predefined for us.

We are going to write all of our code in src/main.s

Clone the repository:

git clone https://github.com/zrezke/8by8snake-template

cd 8by8snake-template

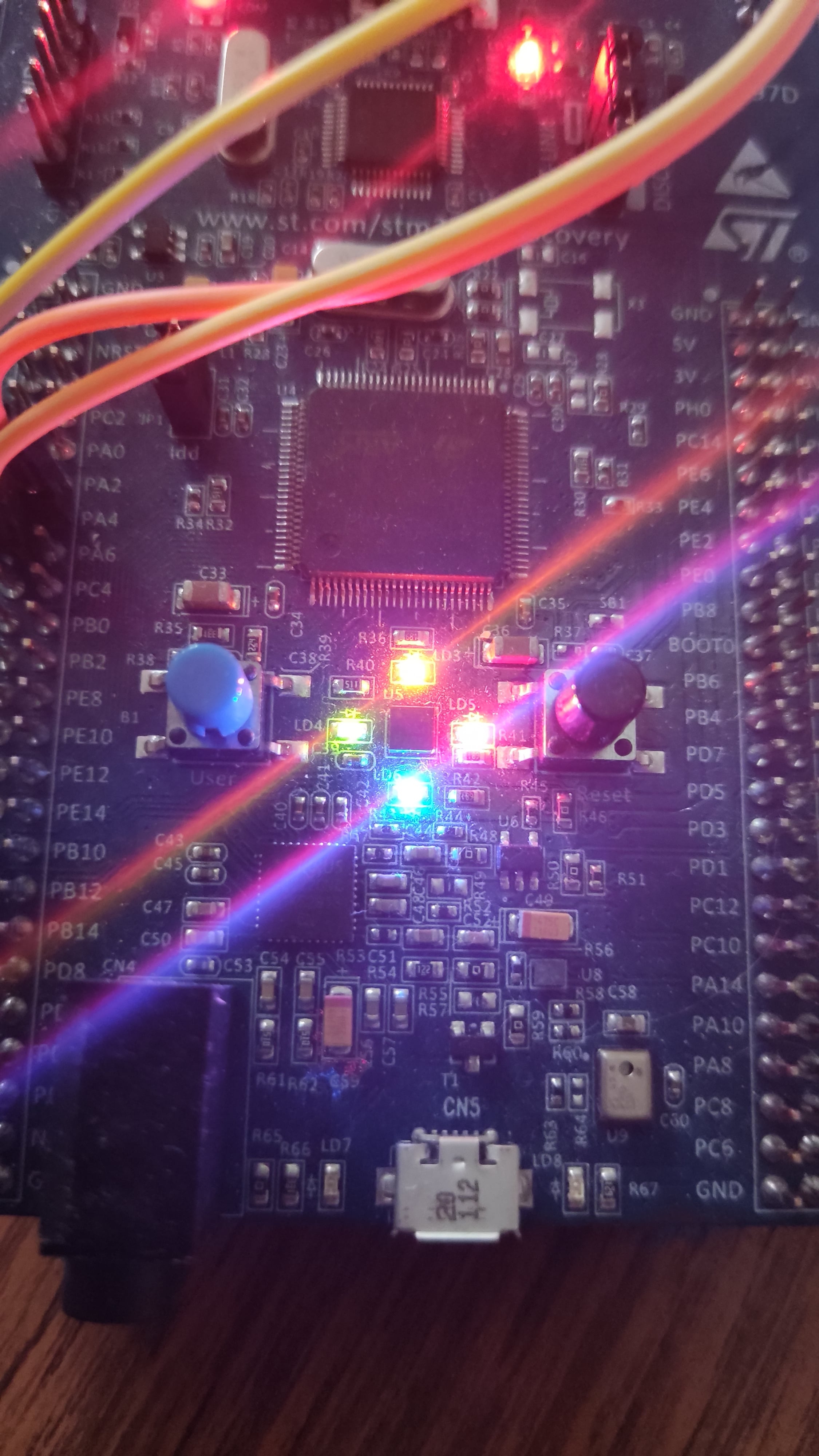

If you now connect your board to your computer and run:

make && make burn

you should see 4 LED-s light up on your device!

If this is not working you might not have tools such as make installed on your machine… Take a look at https://github.com/fcayci/stm32f4-assembly#option-2—custom-development-environment and install the necessary tools!

Communicating with the matrix

We will start by connecting and configuring the LED matrix. As specified in the parts list we will be using an 8x8 LED MATRIX with MAX7219 display driver.

When we talk about communicating with the LED matrix, we are really talking about communicating with the driver.

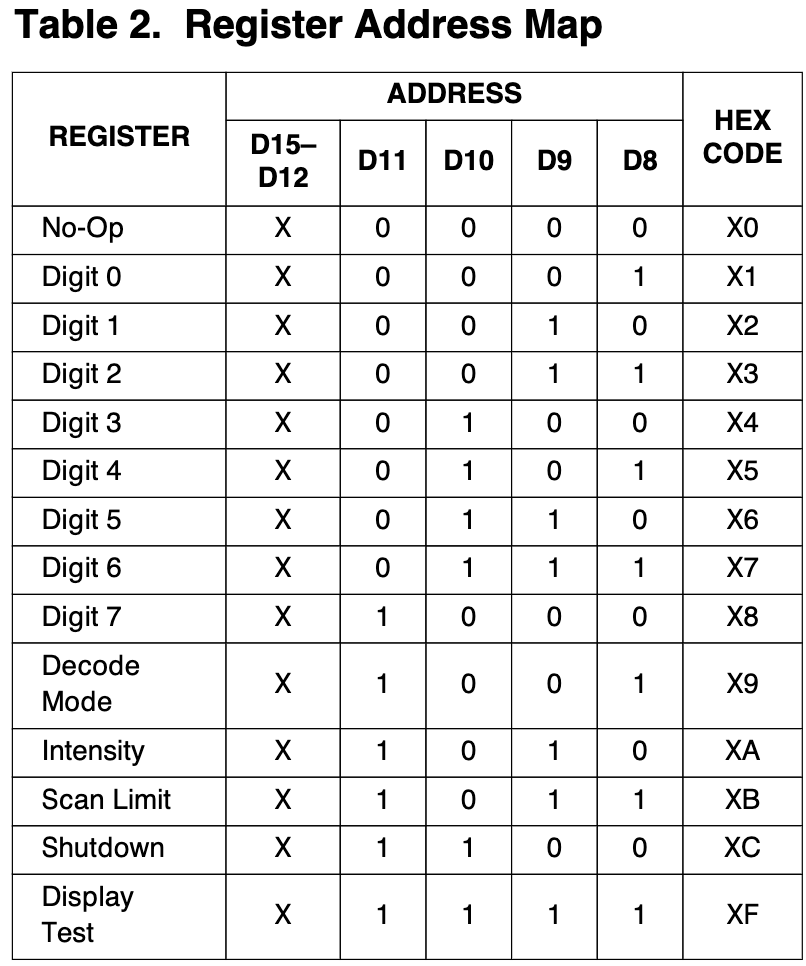

The driver is a chip with 14 registers on it:

There are 6 configuration registers, which configure how the display works, and not really what it displays:

- No-Op

- Can be used to send data to the desired display through other displays when you cascade multiple displays.

- Decode Mode:

- How to treat data in “Digit“ registers: BCD or (column, row)

- Intensity:

- How bright the LEDs are shinning

- Scan Limit

- Which Digit registers to display

- Shutdown

- Shutdown mode enable or disable.

- Display test

- Display test mode enable or disable (DISPLAY TEST = All LEDs light up)

Whats left are 8 digit registers which represent data: What is shown on the display.

The data in these registers can be decoded into BCD code B or can be left as is.

If not decoded, each Digit register represents a column, for example Digit 0 == Column 0, and the 8 bits inside the digit register represent the 8 rows. We will be using no-decode, because we want control over each pixel.

Sending data

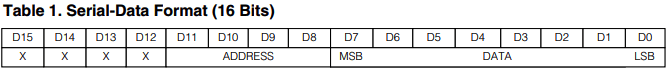

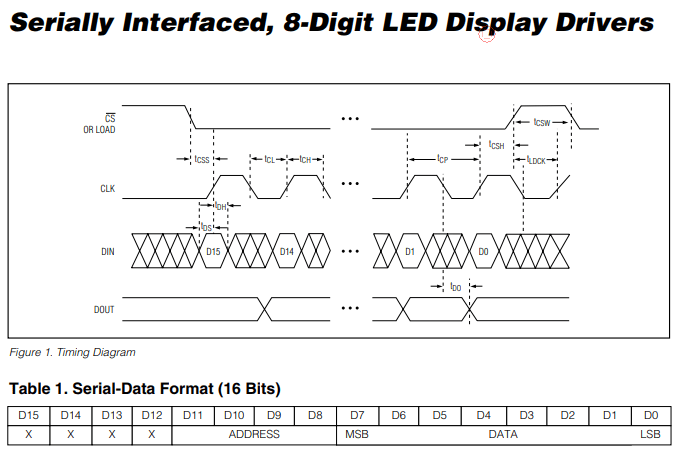

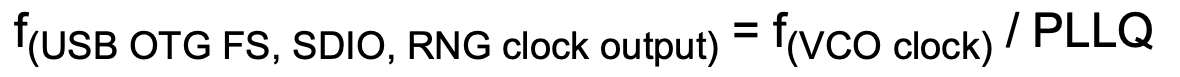

The MAX7219 specifies a data format we need to follow:

As you can see we will be sending 16bit data packets where the 4 MSB bits are don’t care bits.

D11 - D8 are address bits, which tell the MAX7219 in which register to write the D7-D0 data bits.

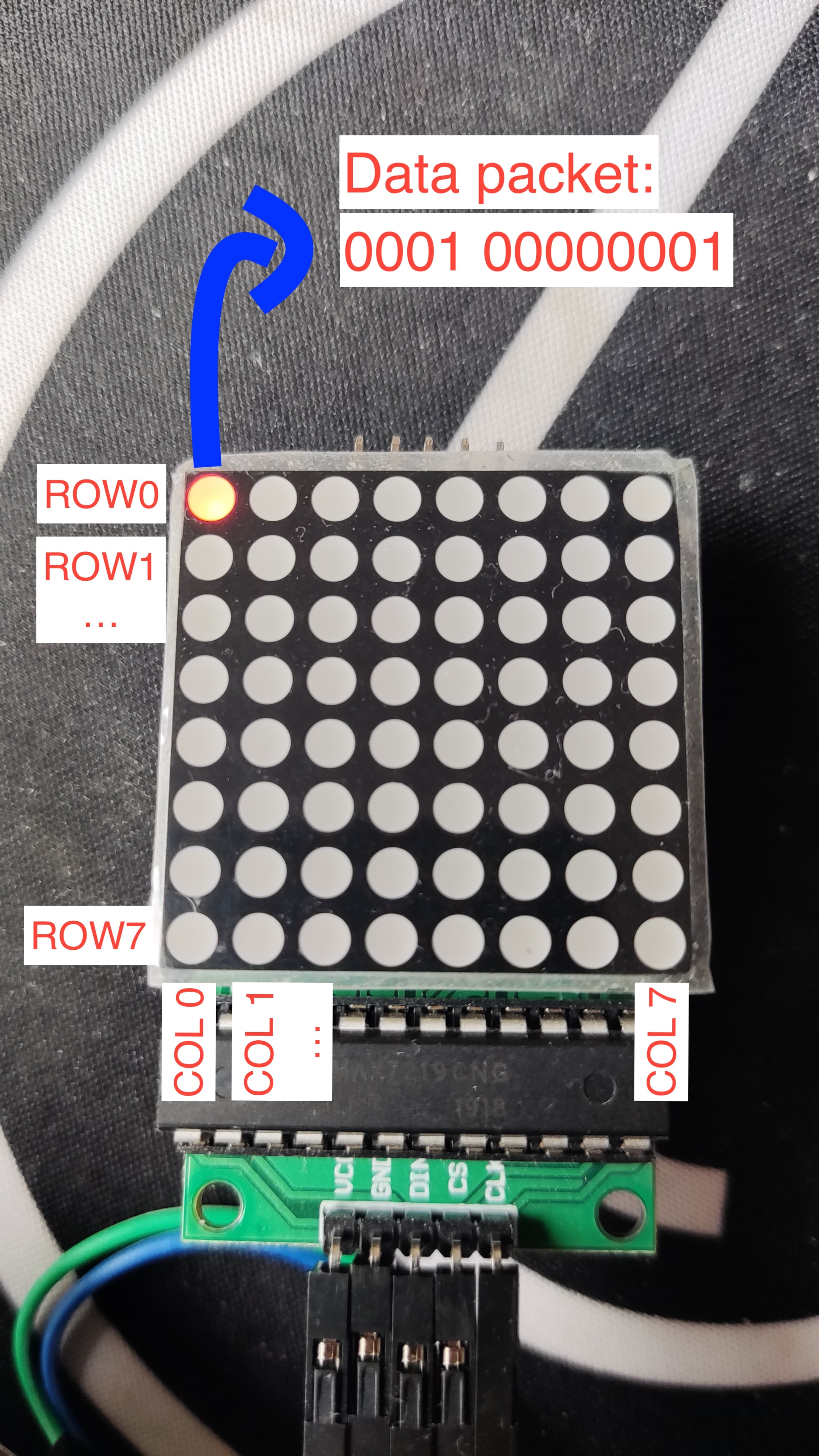

Data packet example:

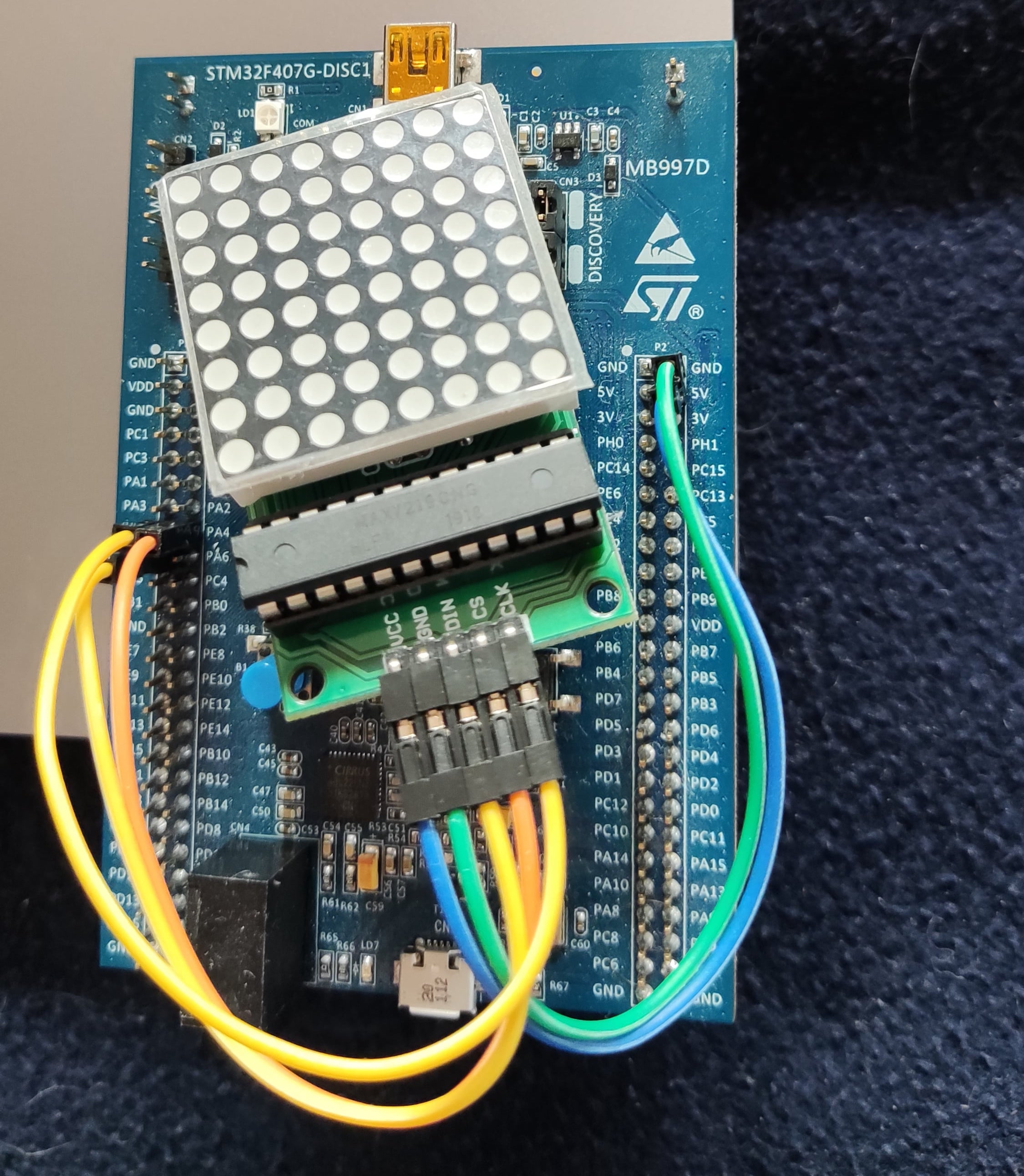

Connecting the LED matrix

PRO TIP: Connect your cables on the bottom side of the STM32 to make the wiring more stable! (not how I did it in the bottom picture)

| LED MATRIX | STM32 |

|---|---|

| VCC | 5v |

| GND | GND |

| DIN | PA7 |

| CS | PA4 |

| CLK | PA5 |

How to send our data packet to the matrix?

The MAX7219 uses SPI to communicate with other devices.

SPI

SPI is a synchronous communication protocol, which uses a clock signal (CLK -> PA5) to synchronize the communication and a Chip Select (CS -> PA4) to enable the chip we are communicating with. Data is sent or received on MOSI (master output slave input) or MISO (master input slave output) (DIN -> PA7).

For our purposes we are going to configure the SPI as a typical master-slave communication where the STM32 will be the master and MAX7219 will be the slave.

SPI on the STM32

STM32 has three SPIs, we will use SPI1.

We will configure the SPI in transmit only mode with software slave management, meaning that we are only going to be writing data to MOSI (Master Out Slave In) pin (PA7) and driving the chip select (PA4) through software.

GPIOA configuration

As you can see in Connecting the LED matrix we are only using PA pins which are pins from the GPIO-A port. Before we can use GPIO-A we have to configure the port and specify how we want to use pins 4, 5 and 7.

We will implement the configuration in a function called init_io, which will be expanded later on when we will configure pins for the joystick input.

GPIOA configuration procedure:

- Enable clock for the GPIO-A port

- Select mode for each pin in GPIOA_MODER register.

- PA4: general purpose output

- PA5 and PA7: alternate function mode.

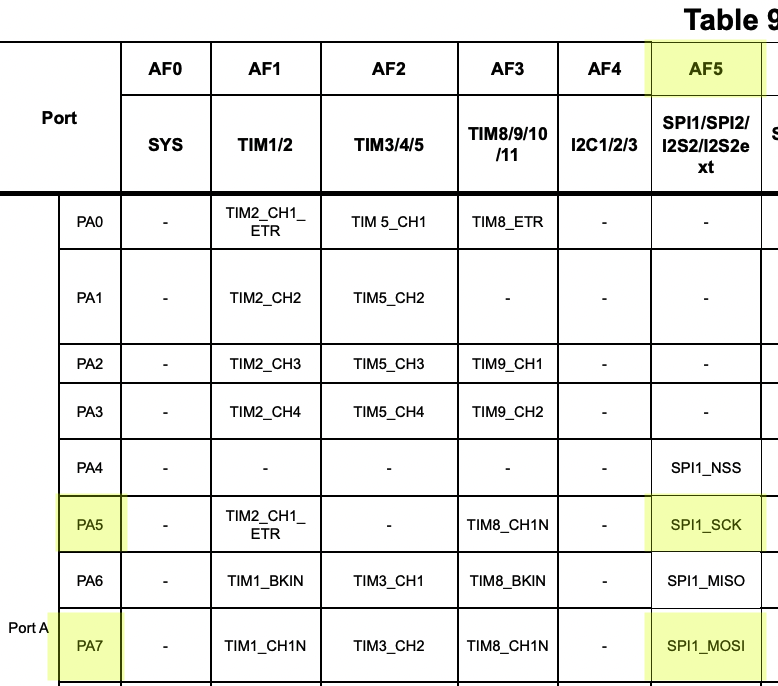

- For PA5 and PA7 select the right alternate function in the GPIOA_AFRL register

- To find the correct alternate function for each pin look for Table 9. Alternate function mapping in the STM32 datasheet

init_io:

push { r5, r6, lr }

// Enable GPIOA clock

ldr r5, =RCC_BASE

ldr r6, [r5, #RCC_AHB1ENR]

orr r6, #1

str r6, [r5, #RCC_AHB1ENR]

// GPIOA_MODER

ldr r5, =GPIOA_BASE

/*

We will use software slave management and manually set and reset chip select,

so set pin 4 as general purpose output

*/

ldr r6, [r5]

orr r6, #(0b01 << 8)

// Select alternate function mode (MODER register) on pins 5 (SPI1 SCK) and 7 (SPI1 MOSI)

orr r6, #(0b10 << 10)

orr r6, #(0b10 << 14)

str r6, [r5]

// Set AF5 (SPI1) for pins 5 and 7

ldr r6, [r5, #GPIO_AFRL]

orr r6, r6, #(0b101 << 28)

orr r6, r6, #(0b101 << 20)

str r6, [r5, #GPIO_AFRL]

// Set chip select high

// We will always pull this pin low before sending data and high after sending data

ldr r6, [r5, #GPIO_ODR]

orr r6, #(1<<4)

str r6, [r5, #GPIO_ODR]

pop { r5, r6, pc }

Add this function somewhere bellow Default_Handler and modify your _start function so we will call init_io when the program starts:

_start:

bl init_io

We have now configured the GPIO pins for SPI. We still need to actually configure the SPI.

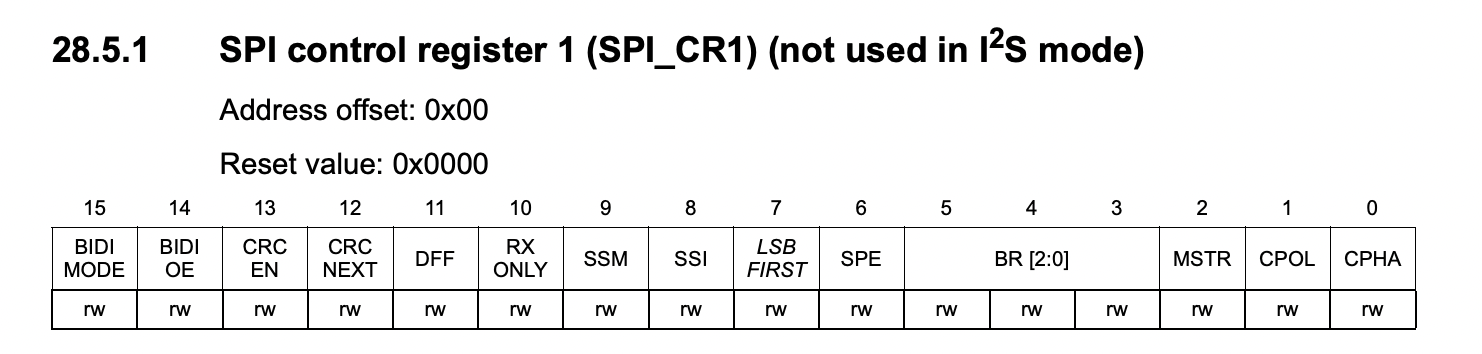

Configuring the SPI

As I said, we will configure STM32 SPI in master, transmit only mode with software slave management. To configure our SPI in such way we need to configure the SPI_CR1 (control register).

SPI_CR1 configuration:

- Configure SPI in master mode:

- Set

MSTR= 1

- Set

- Configure SPI in transmit only mode

- Set

BIDIOE= 1.

- Set

We also have to take into account the data format of MAX7219…

# Note: In the documentation the CS pin of MAX7219 is referred to as LOAD.

From the documentation of MAX7219 we can understand that:

- We need to send 16-bit data packets (MSB sent first), where the 4 MSB bits are don’t care bits and don’t matter but need to be there…

- Set

DFF(Data frame format) = 1 (16-bit) LSBFIRST(Least significant bit first) = 0

- Set

- The data is loaded into a buffer of the MAX7219 chip on each rising edge of the clock.

CPOL(Clock polarity) = 0, Low idle clock.CPHA(Clock phase) = 0, transmit data on rising clock edge.

- The data we sent is loaded from the buffer into the register on the rising edge of LOAD (CS).

- As we are using software slave management, we will always manually reset CS (PA4) before transmitting data and set it again after transmission, so we only need to configure:

SSM(Software slave management) = 1SSI(Internal slave select) = 1

- As we are using software slave management, we will always manually reset CS (PA4) before transmitting data and set it again after transmission, so we only need to configure:

After we have written these values to SPI_CR1 we can enable the SPI by setting SPE (SPI enable) bit in SPI_CR1.

Let’s implement this configuration in a function called init_spi1.

init_spi1:

push { r5, r6, lr }

// ENABLE Clock

ldr r5, =RCC_BASE

ldr r6, [r5, #RCC_APB2ENR]

// Bit 12: SPI1 clock enable

orr r6, #(1 << 12)

str r6, [r5, #RCC_APB2ENR]

// Reset SPI1_CR

ldr r5, =SPI1_BASE

mov r6, 0

str r6, [r5]

// Configure SPI_CR1

mov r6, #0b00 // CPOL,CPHA

orr r6, #(1<<14) // BIDIOE

orr r6, #(1<<2) // MSTR

orr r6, #(0b11<<8) // SSI, SSM

orr r6, #(1<<11) // DFF

str r6, [r5]

// Enable SPI

ldr r6, [r5]

orr r6, #(0b1<<6) // SPE

str r6, [r5]

pop { r5, r6, pc }

Define it bellow Default_Handler and append a call to init_spi1 in _start:

_start:

bl init_io

bl init_spi1

Great! The SPI should now be configured and ready to send data!

Sending data with SPI

Let’s implement a function called transmit_spi1 that will transmit data with SPI.

Our function will receive the data we want to send though register r0 and transmit it on PA7.

Transmission procedure:

- Pull Chip Select (PA4) LOW

- Write data from r0 to SPI_DR (SPI data register)

- Wait until TXE (Transmit buffer empty) in SPI_SR is set high.

- Wait until BSY (SPI busy) in SPI_SR bit is reset.

- Pull Chip Select (PA4) high

- MAX7219 loads data into internal registers on rising edge of CS.

transmit_spi1:

push { r5, r6, lr }

// Pull chip select low

ldr r5, =GPIOA_BASE

ldr r6, [r5, #GPIO_ODR]

eor r6, #(1<<4)

str r6, [r5, #GPIO_ODR]

ldr r5, =SPI1_BASE

transmit_spi1_loop:

ldr r6, [r5, #SPI_SR]

tst r6, #2

beq transmit_spi1_loop

// Transmit contents of r0

str r0, [r5, #SPI_DR]

// Wait for txe, then for bsy

wait_txe_spi1:

ldr r6, [r5, #SPI_SR]

tst r6, #2

beq wait_txe_spi1

wait_bsy_spi1:

ldr r6, [r5, #SPI_SR]

tst r6, #128

bne wait_bsy_spi1

// Pull chip select high

ldr r5, =GPIOA_BASE

ldr r6, [r5, #GPIO_ODR]

orr r6, #(1<<4)

str r6, [r5, #GPIO_ODR]

pop { r5, r6, pc }

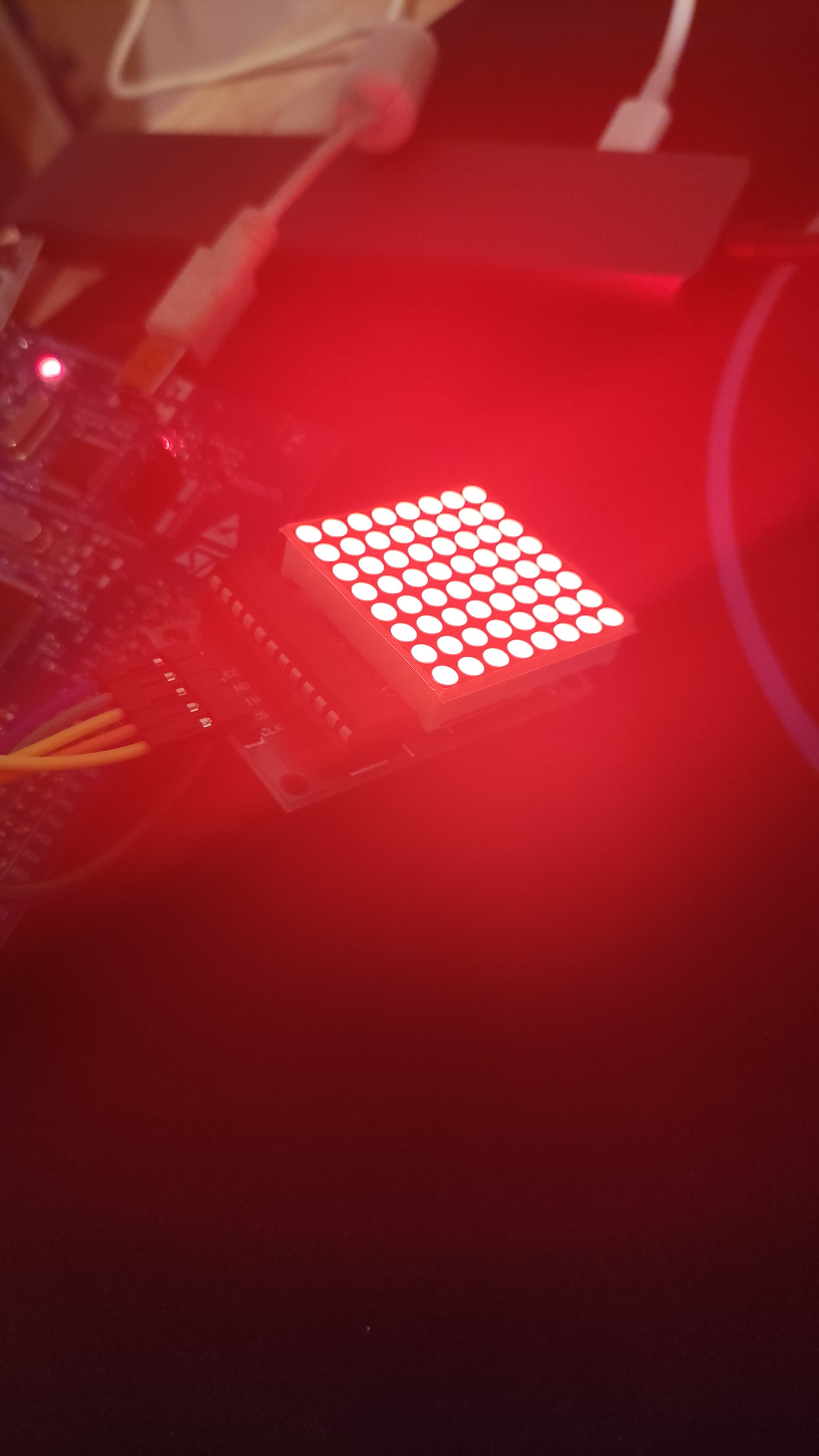

Test if the SPI and the display are working

To test if our communication is working let’s send a data packet which will put the display into TEST MODE. Test mode makes all pixels light up with max brightness.

In the assembly template I have predefined a constant called ADDR_DISPLAY_TEST which is the address of display test register of the MAX7219. In this register we can enable or disable test mode. To enable test mode set LSB of this register to 1.

Temporarily update _start to enable test mode on the display:

_start:

bl init_io

bl init_spi1

ldr r0, =ADDR_DISPLAY_TEST

add r0, #1

bl transmit_spi1

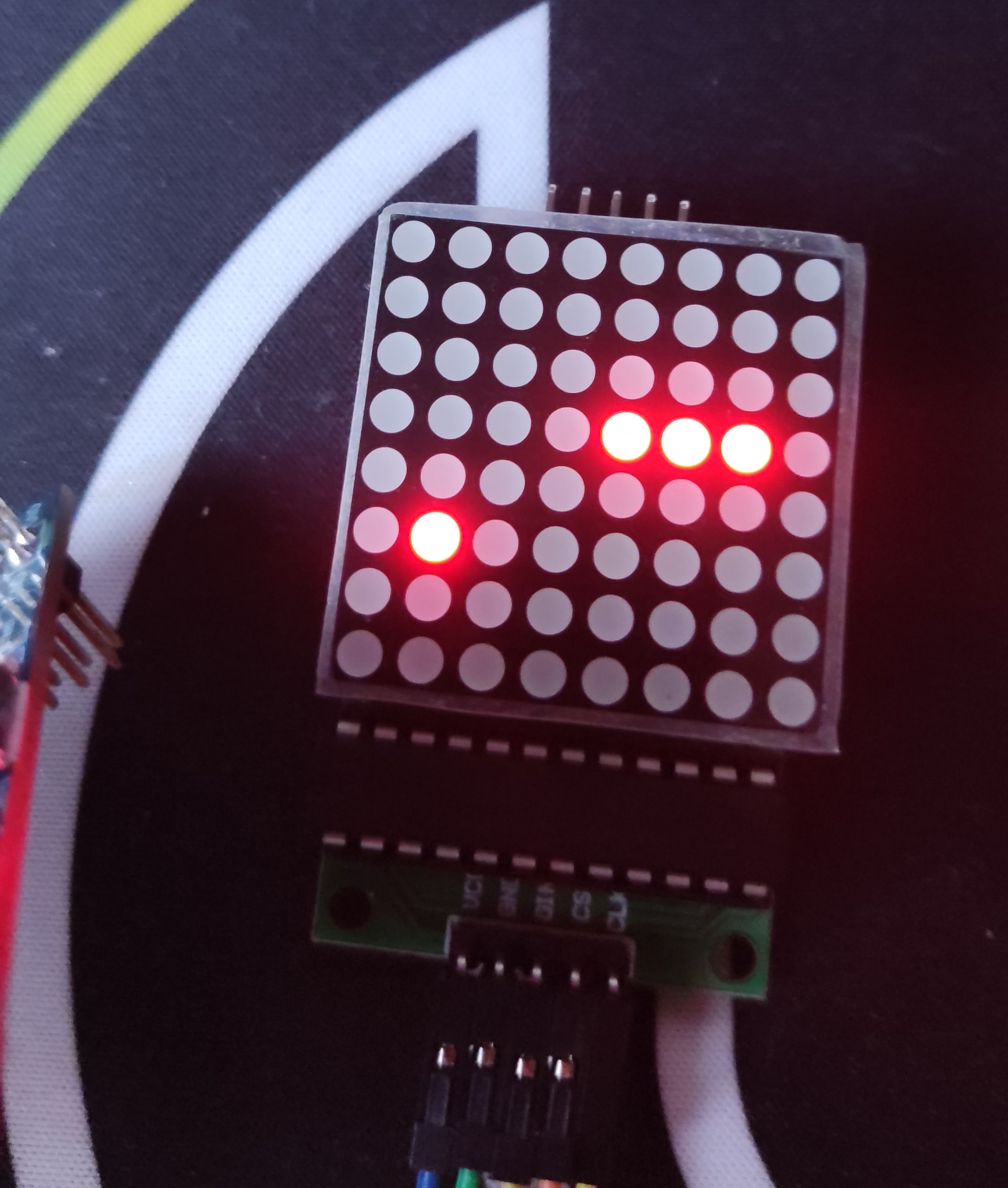

Run: make && make burn and you should see a fully lit up led matrix.

Setting up the display for sending pixel data

First let’s configure the display

There are a 5 registers we need to configure to ensure correct display behavior:

- Shutdown register

- Set normal operation

- Decode register

- Set No Decode for all digits

- Intensity register

- Set to 3/32 intensity (one more than lowest)

- Scan limit register

- Display all digits (columns)

- Display test

- Set normal operation

configure_matrix:

push { r0, lr }

ldr r0, =ADDR_SHUTDOWN

add r0, #1

bl transmit_spi1

ldr r0, =ADDR_DECODE

bl transmit_spi1

ldr r0, =ADDR_INTENSITY

add r0, #1

bl transmit_spi1

ldr r0, =ADDR_SCAN_LIMIT

add r0, #7

bl transmit_spi1

ldr r0, =ADDR_DISPLAY_TEST

bl transmit_spi1

bl clear_display

pop { r0, pc }

Add this function somewhere after Default_Handler and modify _start:

_start:

bl init_io

bl init_spi1

bl configure_matrix

Sending pixel data to the display

Because it is going to come in handy later, we will always keep an internal representation of what is being drawn on the screen in a variable called PIXEL_DATA.

Make sure you define this variable in the .bss section and assign 8 bytes of space to it, or your code will probably not work.

You can imagine PIXEL_DATA as an array of bytes, where the index of the byte is the column index and the byte tells us which rows to light up in that column.

/*

The .section .bss is already included in the asm template,

put the PIXEL_DATA definition there!

*/

.section .bss

PIXEL_DATA: .space 8

Now to send PIXEL_DATA to the display, we are going to write a render function that will loop through PIXEL_DATA and send row data for each column:

render:

push { r0, r1, r2, r5, lr }

bl update_pixel_data

bl clear_display

/*

We will use r3 to store the current column address.

This will be incremented every iteration by 0x100, because this is

how far apart column registers are and we will add this value to the row data from PIXEL_DATA

to get a data packet containing column, row data.

*/

mov r3, #0x100

// Load address of PIXEL_DATA into r5

ldr r5, =PIXEL_DATA

render_loop:

// Load row data stored at r5 and increment r5 for the next iteration

ldrb r0, [r5], #1

// Concatenate column and row data, and transmit it.

orr r0, r3

bl transmit_spi1

// Increment column and check if the end has been reached.

add r3, #0x100

cmp r3, #0x900

bne render_loop

pop { r0, r1, r2, r5, pc }

The render function contains some other functions we haven’t defined yet, so lets do it now.

clear_display:

push { r5, r6, lr }

ldr r0, =COL0

clear_display_loop:

bl transmit_spi1

add r0, #0x100

cmp r0, #0x900

bne clear_display_loop

pop { r5, r6, pc }

update_pixel_data:

push { r5, r6, lr }

ldr r5, =PIXEL_DATA

// Clear pixel data

mov r6, #0

str r6, [r5]

str r6, [r5, #4]

// Draw the top pixel in column 0

mov r6, #1

strb r6, [r5]

pop { r5, r6, pc }

clear_displayclears all column registersupdate_pixel_datacurrently clears PIXEL_DATA and then sets the top pixel in column 0, the result will look like the data packet example. We will modify this function later on to draw the snake. The pixel data always has to be cleared, because we only want to show the latest updated data which is easiest to do by just clearing and rewriting everything. This will become more clear later when we will have constantly changing data (the snake).

Now we will temporarily modify _start to call render:

_start:

bl init_io

bl init_spi1

bl configure_matrix

bl render

Later when we have implement a game loop, we will move render there…

You can now run make && make burn and the result should look like this:

![]()

We now have everything ready to start implementing a snake!

Programming the snake

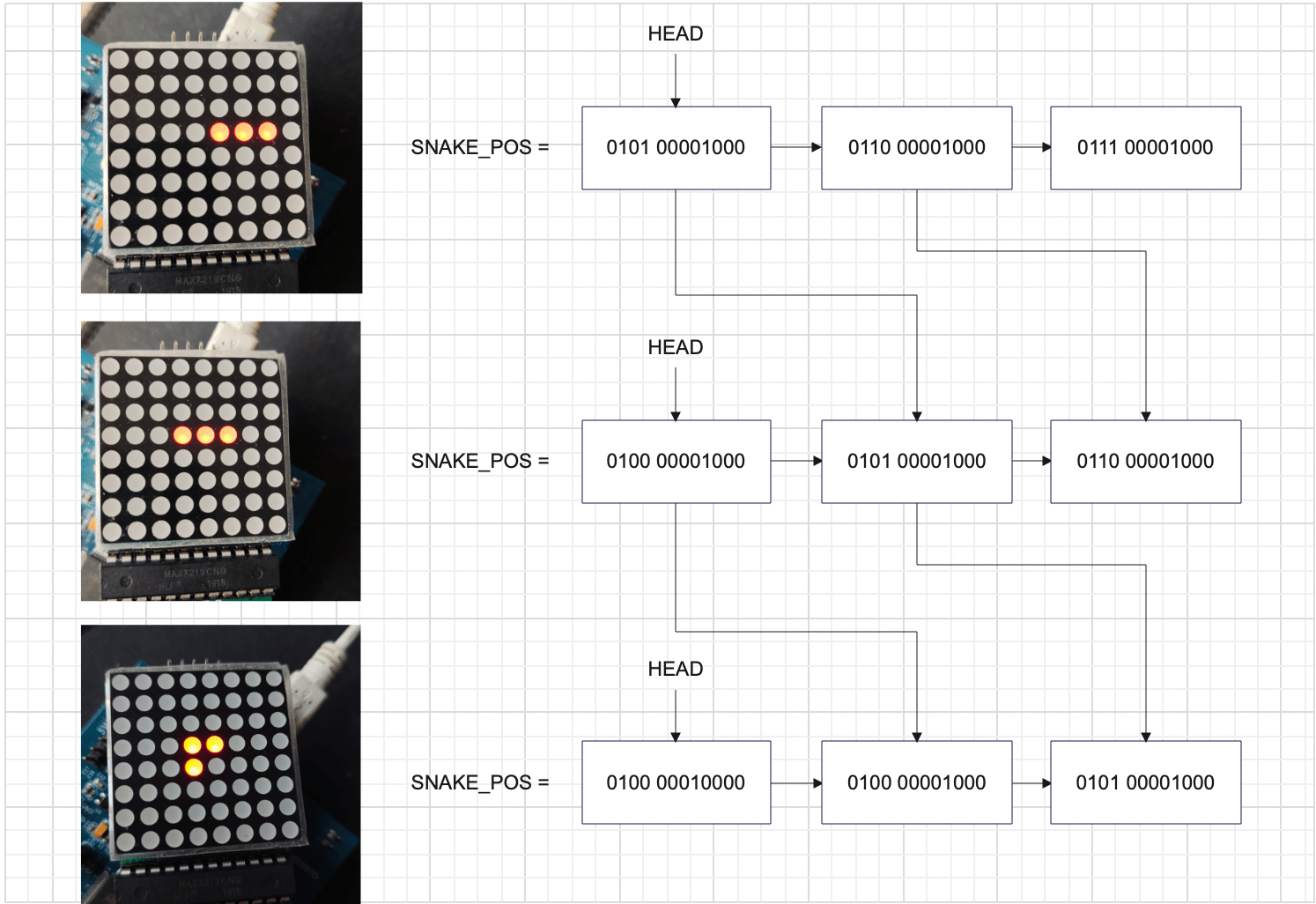

Programming the snake is easier than you might think. You can think of a snake as a list that stores body part positions, where each time the snake moves, the values stored in the list shift by one. So for example the position that was stored at index 0 (snake head) gets shifted to index 1 and so on. Now for actually moving the snake left, right, up or down you only have to move the head one pixel left, right, up or down and the rest of the snake will follow. Super simple!

As you can see in the sketch, we are going to call this list SNAKE_POS, we will also need to keep the length of the snake: SNAKE_LENGTH and the direction the snake is heading in: DIRECTION.

// Define in bss section

SNAKE_POS: .space 128 //(8x8 x Half Word (we are storing the full data packet))

SNAKE_LENGTH: .space 1

DIRECTION: .space 1

/* SNAKE DIRECTION

0 -> left

1 -> right

2 -> up

3 -> down

*/

Updating snake position

With these variables defined we can start creating a snake updating function, which will be moving the snake.

We will first check which direction we have to move in and jump into one of move_{left, right, up, down} functions, where we will create the new head position and store it in r0. Then in move_snake, the snake will get shifted in memory. To do this we will loop from the back, moving the second to last body part to the end of the snake and so on, until we have moved the head position (which is still the old head position, not the new one in r0). After we have shifted the snake, we override the old head position with the new one from r0.

update_snake:

push { r4, r5, r6, lr }

// Load head position into r0, because move_{left,right...} functions expect it in r0

ldr r4, =SNAKE_POS

ldrh r0, [r4]

// Load direction and jump into the appropriate function

ldr r5, =DIRECTION

ldrb r6, [r5]

cmp r6, #0

beq move_left

cmp r6, #1

beq move_right

cmp r6, #2

beq move_up

cmp r6, #3

beq move_down

// Shift the snake in memory

move_snake:

// Already have SNAKE_POS address in r4

ldr r3, =SNAKE_LENGTH

ldrb r3, [r3]

// Multiply length by 2 because of HWROD

add r3, r3, r3

sub r3, #2

move_snake_loop:

ldrh r2, [r4, r3]

add r3, #2

strh r2, [r4, r3]

subs r3, #4

cmp r3, #-2

bne move_snake_loop

strh r0, [r4]

pop { r4, r5, r6, pc }

Now we have to define the move_{left, right, up, down} functions.

I am only going to define left and up here because right and down are very similar, you can find them in my repository or implement them yourself.

Move left

For the move_left, we have to subtract one column (0x100) from the position stored in r0 and then check if we have gone out of the display range. If that happened we want to spawn the head on the right end of the screen in the same row. To do so, add 0x800 to r0. This translates to column7 (last column) + whatever row that is stored in r0.

move_left:

sub r0, 0x100

cmp r0, #0x100

it lt

addlt r0, #0x800

b move_snake

Move up

Moving up is a little more complicated, because we have to shift the row bits while preserving the column information.

To shift the rows without changing columns we are going to extract the row bits from r0 by and-ing it with 0xFF and storing the result in r1. From there we can simply right shift r1 by one bit and we have essentially just moved one row up. If 0 is in r1, this means we have gone over the top of the display. If this happens we write 128 to r1 which spawns the head in the bottom row.

Now we have to stitch together the new row data and the old column data. In r0 we still have the (old) full position. We will and r0 with 0xF00, which will only keep the column info in r0. After this we just merge r0 and r1 together by or-ing them and thats it, our new head position is stored in r0!

move_up:

and r1, r0, #0xFF

mov r1, r1, lsr 1

cmp r1, #0

it eq

moveq r1, #128

and r0, #0xF00

orr r0, r1

b move_snake

The game loop

We now basically have all the functions to make a moving snake. However we are yet to develop a game loop.

A game loop is pretty simple, it’s a never ending loop that updates and renders the game.

We can write a simple game loop like this:

/* !IMPORTANT

Define this after _start but before Default_Handler,

so the game_loop will start executing instead of Default_Handler,

after _start.

*/

game_loop:

bl update_snake

bl render

b game_loop

Now remove bl render from _start:

_start:

bl init_io

bl init_spi1

bl configure_matrix

In our case we have to slow the loop down because, if we leave it like this the game will update like 16 million times a second and the snake will move with supersonic speed.

For this slow down we are going to use the Systick timer, a timer that is part of Cortex-M4 itself (not an STM32 peripheral).

Systick timer configuration

As with any other peripheral we have to write a configuration function.

We will configure the timer so that it triggers an interrupt every 200ms, giving us an indication that it is time to update and render the game again.

To do this the timer needs to be configured in counter mode with interrupt enabled and a reload value of 3199999, which takes 200ms to count down to zero from.

For more detail look at:

- Systick documentation: I couldn’t find it for Cortex M4, but it is the same.

init_tc:

push {r5, r6, lr}

ldr r6, =SCS

ldr r5, =SYSTICK_RELOAD_200MS

str r5, [r6, #SCS_SYST_RVR]

// Reset value

mov r5, #0

str r5, [r6, #SCS_SYST_CVR]

// Enable counter

orr r5, #1

// Enable interrupt

orr r5, #2

// Processor clock as clock source

orr r5, #4

str r5, [r6, #SCS_SYST_CSR]

pop {r5, r6, pc}

Now append init_tc to _start:

_start:

bl init_io

bl init_spi1

bl configure_matrix

bl init_tc

Since the systick timer will generate an interrupt, we need a function that will handle this interrupt.

Interrupt handler:

.global SysTick_Handler

.type SysTick_Handler, %function

SysTick_Handler:

push { r5, r6, lr }

// Reset UPDATED

ldr r5, =UPDATED

mov r6, #0

strb r6, [r5]

pop { r5, r6, pc }

The interrupt handler resets a variable called UPDATED.

You can think of UPDATED as a boolean, telling our program if the game has already been updated.

If the game has been updated, we will not update it again until the Systick rolls over (end of 200ms) and resets UPDATED in the interrupt handler.

Let’s add this functionality to the game loop:

game_loop:

// Check if already updated

// If updated jump back to game_loop (loop continuously)

ldr r0, =UPDATED

ldrb r0, [r0]

cmp r0, #1

beq game_loop

// If game hasn't been updated yet: update it and set UPDATED = 1

bl update_snake

bl render

ldr r1, =UPDATED

mov r0, #1

strb r0, [r1]

b game_loop

UPDATED definition:

// bss section

UPDATED: .space 1

Initializing a snake

Let’s populate SNAKE_POS with some initial body parts.

At the start we are always going to spawn a snake of length 3 with its head at column 4, row 3, facing in the left direction.

init_snake:

push { r5, r6, lr }

// Init length

ldr r5, =SNAKE_LENGTH

mov r6, #3

strb r6, [r5]

// Init direction

ldr r5, =DIRECTION

mov r6, #0

strb r6, [r5]

// Place body parts

ldr r6, =SNAKE_POS

ldr r5, =COL5+8

strh r5, [r6], #2

add r5, #0x100

strh r5, [r6], #2

add r5, #0x100

strh r5, [r6]

pop { r5, r6, pc }

Append init_snake to _start:

_start:

bl init_io

bl init_spi1

bl configure_matrix

bl init_snake

This code should work, unfortunately we currently don’t have a function to render SNAKE_POS to the display.

You might be thinking why not just loop through SNAKE_POS and send every body part to the display? The problem with that is; think about what happens when, say two body parts are in the same column; for example when moving vertically… We will send a data packet for the first body part and then for the second. When we send the second body part we will be overwriting (resetting) the previous body part’s row essentially just rendering one pixel every time.

Rendering the snake

This is where our PIXEL_DATA will come in handy. We are going to assemble the SNAKE_POS into PIXEL_DATA we can send to the screen.

Let’s update our update_pixel_data function

We are going to loop through SNAKE_POS and find out which column the body part is in, then join the row of the body part with existing row data for that column in PIXEL_DATA.

update_pixel_data:

push { r0, r1, r2, r3, r4, r5, r6, lr }

ldr r5, =PIXEL_DATA

// Clear pixel data

mov r6, #0

str r6, [r5]

str r6, [r5, #4]

// Draw snake

ldr r4, =SNAKE_LENGTH

ldrb r4, [r4]

add r4, r4, r4

ldr r3, =SNAKE_POS

add r4, r4, r3

update_snake_pixels_loop:

// Load one snake pixel

ldrh r2, [r3], #2

// Find out column of pixel

mov r1, r2, lsr #8

sub r1, #1

// Extract row data from snake pixel

and r2, 0xff

// Orr row data with pixels that are already in same column

ldrb r0, [r5, r1]

orr r0, r2

// Store, loop again till you reach the end of the snake

strb r0, [r5, r1]

cmp r3, r4

bne update_snake_pixels_loop

// TODO: Draw food

pop { r0, r1, r2, r3, r4, r5, r6, pc }

Now run make && make burn. If everything went to plan you should see a snake appear and start moving left.

Changing the direction

We now have something that looks and moves like a snake, but only in one direction.

We don’t actually have any way of changing the direction yet.

As was mentioned in the intro, we will be using a joystick module to control the snake.

The joystick

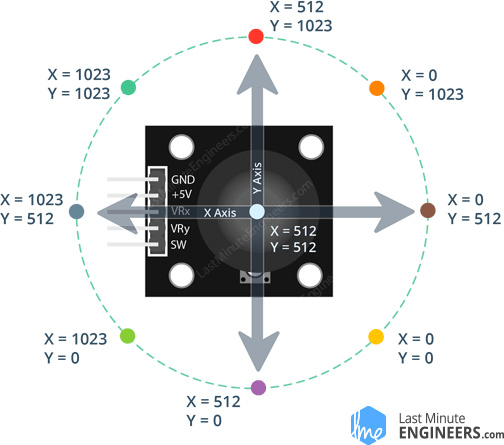

The joystick is essentially just two potentiometers, one for the X and one for the Y axis.

By moving the stick you move the potentiometer, thereby adjusting the resistance. More resistance = less voltage and vice versa. These voltages can be read on VRx and VRy pins of the joystick.

Getting joystick input

Joystick VRx and VRy are meant to be used as analog inputs which give us a voltage on the range of [0V - 5V]. To represent analog values in a computer, we have to convert them to digital representations. For this purpose the STM32 has (two) Analog to Digital Converters (ADC).

We are going to be using ADC2 with a resolution of 10-bits, giving us a range of [0 - 1024].

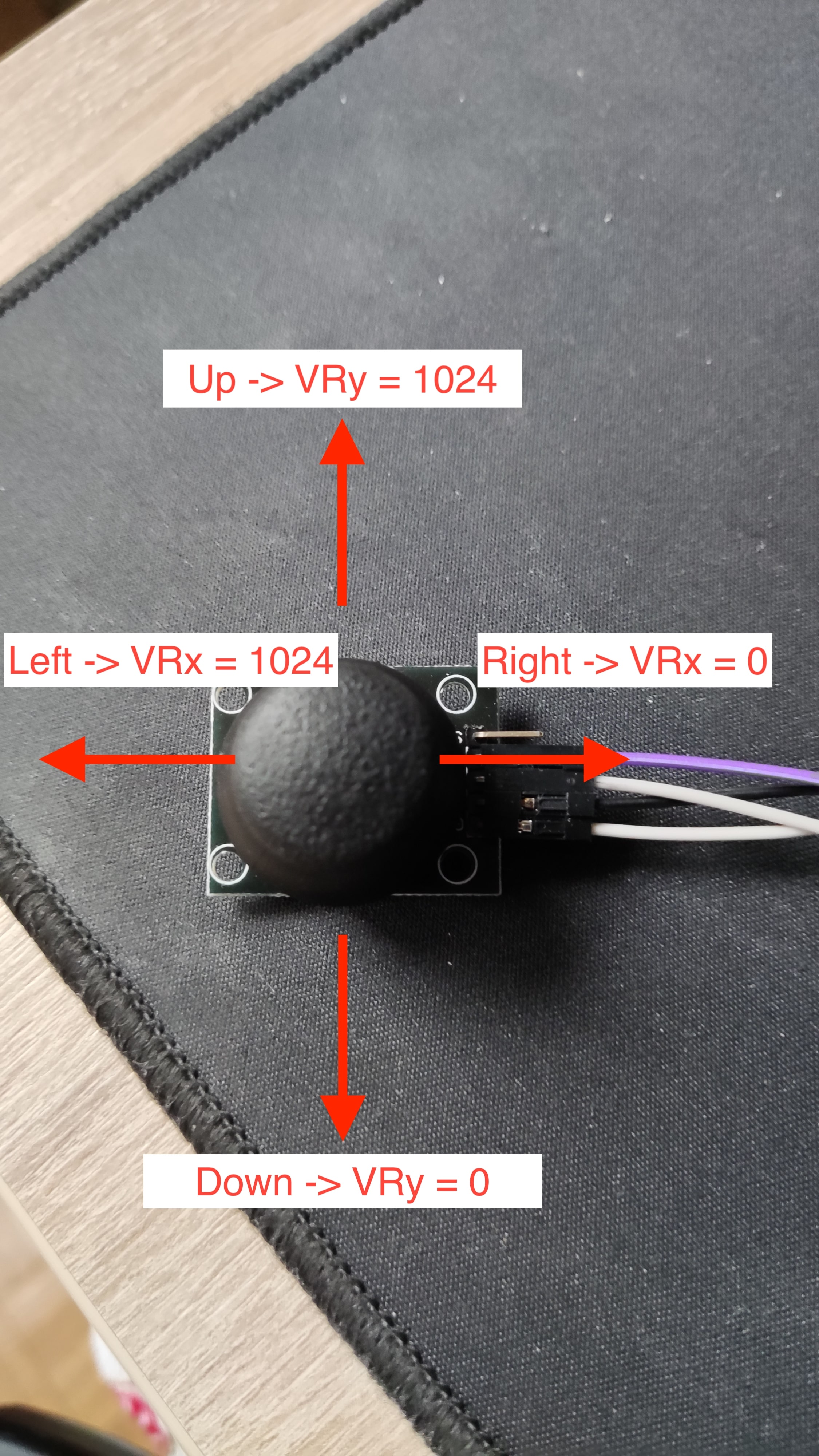

Also I will be using my joystick in the position shown in the photo bellow, so my left, right, up and down won’t confuse you.

We will store converted VRx and VRy in a variable called JOYSTICK_POS

Define JOYSTICK_POS:

// .bss section

.align

JOYSTICK_POS: .space 4

JOYSTICK_POS has 4 bytes. As we are using 10bit AD conversion and we have two inputs to convert, we need at least 10bits for each input to be stored, so we will be using the first 2 bytes to store VRx and the second two bytes to store VRy.

Connections

| Joystick | STM32 |

|---|---|

| GND | GND |

| +5V | +5V |

| VRx | PA1 |

| VRy | PA2 |

I will be using pins PA1 and PA2 for VRx and VRy respectively.

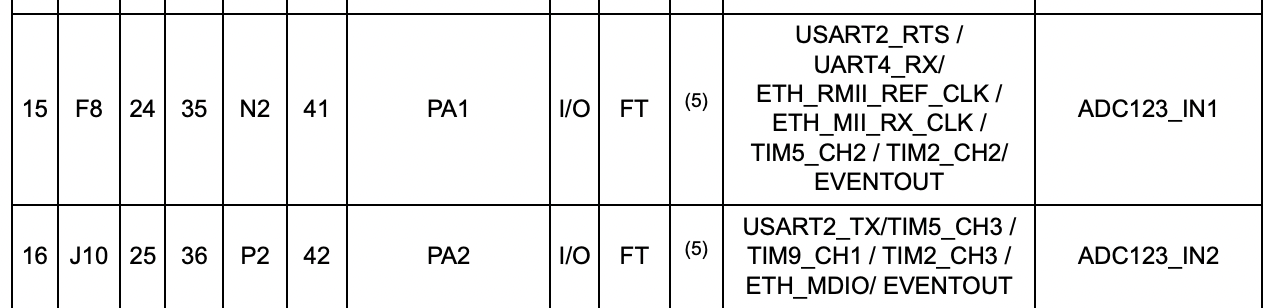

You can choose any of the pins that are connected to ADC2. To find eligible pins look for Table 7. STM32F40xxx pin and ball definitions in the datasheet.

As you can see PA1 and PA2 both have ADC123_IN listed as additional functions.

Now to actually use these pins as analog inputs we have to configure them as such.

Let’s update out init_io function to configure PA1 and PA2 as analog gpio.

init_io:

...

// Merge the following lines with what is already in init_io

// GPIOA_MODER

ldr r5, =GPIOA_BASE

// set pins 1,2 as analog

ldr r6, [r5]

orr r6, #(0b11 << 2)

orr r6, #(0b11 << 4)

...

ADC with DMA

With our inputs now configured we can start configuring the ADC. The ADC requires us to read the converted value in it’s data register before the next one gets converted, if we fail to do that the conversion will stop. We could configure an ADC interrupt and store the data using assembly each time the interrupt gets generated, but in our case this will eat up practically all of our CPU time, since we wil continuously convert joystick input. As the title suggests we will use our ADC in combination with a Direct Memory Access controller (DMA), which allows us to offload the task of reading and storing ADC data from the CPU to the DMA.

ADC configuration

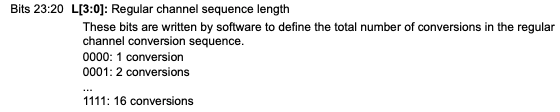

Each ADC has 16 channels that can be converted. You can specify how many channels you want to convert in the L bits of the ADC_SQR1.

And you can tell the order of conversions in this and the other two SQR registers.

We are going to be continuously converting two ADC channels, PA1 on channel 1 and PA2 on channel 2. We will be using SCAN mode, to convert our channels in sequence one after another.

Initializing ADC1:

- Enable ADC1 clock (set ADC1EN in RCC_APB2ENR)

- Set resolution to 10 bits.

- Enable scan mode (set SCAN in ADC_CR1)

- Scan mode makes the ADC convert all channels that we specify in ADC_SQR registers in round robin fashion.

- Set CONT bit, continuous conversion (set CONT in ADC_CR2)

- Enables continuous conversion, so ADC doesn’t stop after we have converted all channels.

- Enable setting EOC flag after each conversion (set EOCS in ADC_CR2)

- Enable DMA and DDS (set DMA and DDS in ADC_CR2)

- Since we will use DMA to transfer data to memory, we need to tell this to the ADC (set DMA bit).

- We also set DDS bit so that the ADC keeps issuing DMA requests as long as data are converted and DMA bit is set.

- Set 2 conversions as regular channel sequence length (set L as 0b1 in ADC_SQR1)

- Select order of conversions as -> PA1, PA2. (ADC_SQR3 register)

- Enable the ADC (ADC1) (ADON bit in ADC_CR2)

init_adc1:

push { r5, r6, lr }

// Enable ADC1 clock

ldr r5, =RCC_BASE

ldr r6, [r5, #RCC_APB2ENR]

orr r6, #(1<<8)

str r6, [r5, #RCC_APB2ENR]

ldr r5, =ADC1_BASE

mov r6, #0

// CR1 settings

// Set RES to 10bits

mov r6, #(0b01<<24)

// SCAN MODE

orr r6, #(1<<8)

// EOCIE

// orr r6, #(1<<5)

str r6, [r5, #ADC_CR1]

//CR2 settings

// set CONT mode

mov r6, #0b10

// EOC after each conversion

orr r6, #(1<<10)

// Enable DMA, DDS

orr r6, #(0b11<<8)

str r6, [r5, #ADC_CR2]

// Two conversions

mov r6, #(1<<20)

str r6, [r5, #ADC_SQR1]

// Select order, PA1, PA2

mov r6, #1

orr r6, #(2 << 5)

str r6, [r5, #ADC_SQR3]

// SAMPLE TIME

mov r6, #9

str r6, [r5, #ADC_SMPR2]

// Enable ADC1

ldr r6, [r5, #ADC_CR2]

orr r6, #1

str r6, [r5, #ADC_CR2]

pop { r5, r6, pc }

Add init_adc1 to _start:

_start:

bl init_io

bl init_spi1

bl configure_matrix

bl init_tc

bl init_adc1

bl init_snake

Our ADC1 is now configured, but not yet started. We will not start our ADC1 until we have the DMA ready, to prevent overrun errors.

Configuring the DMA

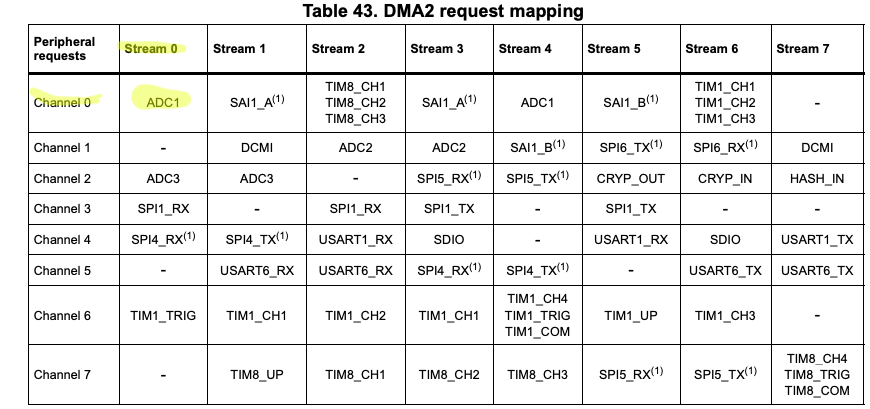

We will be using DMA2 as this is the DMA controller connected to ADC1.

Configuration:

- Enable DMA2 clock

- Reset DMA_S0CR

- Wait for EN bit in DMA_S0CR to reset.

- Reset DMA_LISR and DMA_HISR registers.

- Select Channel 0 (CHSEL bits in DMA_S0CR)

- Select direction peripheral to memory (DIR bits in DMA_S0CR)

- Set peripheral data size and memory data size as half word, because ADC resolution is set to 10 bit. (PSIZE, MSIZE in DMA_S0CR)

- Set priority level as very high (PL bits in DMA_S0CR)

- Enable circular mode (CIRC bit in DMA_S0CR)

- Reload number of items to be transferred (DMA_S0NDTR) each time the value reaches 0.

- Enable memory increment mode (MINC bit in DMA_S0CR)

- Will increment memory location pointer by half word each time a transfers happens.

- This will enable us to write VRx position to first half word of JOYSTICK_POS and VRy to the second one…

- Will increment memory location pointer by half word each time a transfers happens.

- Set 2 as the number of data items to transfer (DMA_S0NDTR register)

- Set Stream0 peripheral address in DMA_S0PAR register as:

ADC1_BASE + ADC_DR(data register of ADC1) - Set Stream0 memory address in DMA_S0MAR as address of

JOYSTICK_POS - Enable Stream0, (EN bit in DMA_S0CR)

init_dma2:

push { r5, r6, lr }

// Enable DMA2 clock

ldr r5, =RCC_BASE

ldr r6, [r5, #RCC_AHB1ENR]

orr r6, #(1<<22)

str r6, [r5, #RCC_AHB1ENR]

ldr r5, =DMA2_BASE

mov r6, #0

str r6, [r5, #DMA_S0CR]

wait_dma2_s0_reset:

ldr r6, [r5, #DMA_S0CR]

tst r6, #1

bne wait_dma2_s0_reset

mov r6, #0

str r6, [r5, #DMA_LISR]

str r6, [r5, #DMA_HISR]

// CHSEL: 0, DIR: Peripheral to memmory,

mov r6, #0

// PSIZE, MSIZE hword

orr r6, #(0b01<<11)

orr r6, #(0b01<<13)

// Priority very high

orr r6, #(0b11 << 16)

// CIRC MODE ENABLE

orr r6, #(1<<8)

// TCIE = 1

orr r6, #(1<<4)

// MEMORY INC

orr r6, #(1<<10)

str r6, [r5, #DMA_S0CR]

// N of data items to transfer: 2

mov r6, #2

str r6, [r5, #DMA_S0_NDTR]

ldr r5, =DMA2_BASE

ldr r6, =ADC1_BASE + ADC_DR

str r6, [r5, #DMA_S0PAR]

ldr r6, =JOYSTICK_POS

str r6, [r5, #DMA_S0M0AR]

// Enable stream

ldr r6, [r5, #DMA_S0CR]

orr r6, #1

str r6, [r5, #DMA_S0CR]

pop { r5, r6, pc }

Add init_dma2 to _start:

_start:

bl init_io

bl init_spi1

bl configure_matrix

bl init_tc

bl init_adc1

bl init_dma2

bl init_snake

Starting the ADC

Now that our ADC and DMA are configured we can start the ADC.

start_adc1:

push { r5, r6, lr }

ldr r5, =ADC1_BASE

// Reset status register

mov r6, #0

str r6, [r5, #ADC_SR]

// START

ldr r6, [r5, #ADC_CR2]

orr r6, #(1<<30)

str r6, [r5, #ADC_CR2]

Start adc1 in _start:

_start:

bl init_io

bl init_spi1

bl configure_matrix

bl init_tc

bl init_adc1

bl init_dma2

bl start_adc1

bl init_snake

Direction changes

We can now start writing out a function that will update our DIRECTION variable.

To update DIRECTION we will call our update_direction function once for each game loop iteration.

The function will check the current direction, then if we are currently moving horizontally we only have to check the vertical axis (check_y), else if we are moving vertically we only check the horizontal axis (check_x), to see if the joystick is in a position we consider a direction change (look at the table bellow).

check_x:

| DIRECTION | VRx |

|---|---|

| No change | 200 <= VRx <= 800 |

| LEFT | VRx > 800 |

| RIGHT | VRx < 200 |

check_y:

| DIRECTION | VRy |

|---|---|

| No change | 200 <= VRy <= 800 |

| UP | VRy > 800 |

| DOWN | VRy < 200 |

update_direction:

push { r2, r3, r4, r5, r6, lr }

ldr r6, =JOYSTICK_POS

ldr r3, =DIRECTION

ldrb r2, [r3]

cmp r2, #2

blt check_y

bge check_x

check_x:

ldrh r5, [r6]

cmp r5, #800 // Joystick is pointing left

itt gt

movgt r2, #0

strbgt r2, [r3]

cmp r5, #200 // Joystick is pointing right

itt lt

movlt r2, #1

strblt r2, [r3]

b exit_update_direction

check_y:

ldrh r5, [r6, #2]

cmp r5, #800 // Joystick is pointing up

itt gt

movgt r2, #2

strbgt r2, [r3]

cmp r5, #200 // Joystick is pointing down

itt lt

movlt r2, #3

strblt r2, [r3]

exit_update_direction:

pop { r2, r3, r4, r5, r6, pc }

Now update game_loop:

game_loop:

// Check if already updated in ongoing game loop and wait until next loop begins

ldr r0, =UPDATED

ldrb r0, [r0]

cmp r0, #1

beq game_loop

bl update_direction

bl update_snake

bl render

ldr r1, =UPDATED

mov r0, #1

strb r0, [r1]

b game_loop

Run make && make burn. If everything went OK you should now be able to use the joystick to control the snake like this:

Food

Let’s add food to the game.

Food will be represented as one pixel, that will light on. To store the position of the food we will create a new variable called FOOD_POS.

// .bss section

FOOD_POS: .space 2

We will need to create a function that will spawn the food in a random location and a function to eat the food and make our snake bigger.

Generating a random food position

We will need to generate two random numbers, one for the column and one for the row index.

To generate random numbers we can use the hardware Random Number Generator (RNG) of the STM32.

Initializing RNG

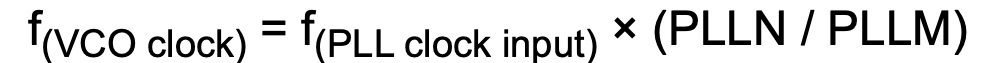

The RNG requires a bit of a special clock configuration. We need to configure the PLL so that the second PLL output clock, which is connected to the RNG is 48Mhz or lower.

We can configure this in the RCC_PLLCFGR register.

Using the following formulas you can configure PLLQ, PLLN, PLLM in RCC_PLLCFGR register, so that f(RNG clock output) = 48Mhz.

- f(PLL clock input) = 16Mhz (by default (HSI clock))

After the RCC_PLLCFGR is configured, enable the RNG clock in RCC_AHB2ENR and enable the PLL in RCC_CR.

Then after we have the clock configured we follow the steps from the 24.3.1 Operation section of the STM32 Reference manual to configure the RNG.

init_rng:

push { r5, r6, lr }

ldr r5, =RCC_BASE

// PLL config RNG_OUT = ((PLL_IN -> 16mhz) * (PLLN/PLLM)) / PLLQ = 48mhz

// set PLLM as 2

mov r6, #2

// Set PLLN as 12

orr r6, #(12<<6)

// Set PLLQ as 2

orr r6, #(2<<24)

str r6, [r5, #RCC_PLLCFGR]

// Enable RNG clock

ldr r6, [r5, #RCC_AHB2ENR]

orr r6, #(1<<6)

str r6, [r5, #RCC_AHB2ENR]

// Enable PLL

ldr r6, [r5, #RCC_CR]

orr r6, #(1<<24)

str r6, [r5, #RCC_CR]

ldr r5, =RNG_BASE

// Turn off rgn, reset SR

mov r6, #0

str r6, [r5, #RNG_CR]

str r6, [r5, #RNG_SR]

// Start RNG

mov r6, #4

str r6, [r5, #RNG_CR]

// Wait for first number and read it

wait_first_rng:

ldr r6, [r5, #RNG_SR]

tst r6, #1

beq wait_first_rng

ldr r6, [r5, #RNG_DR]

pop { r5, r6, pc }

Add init_rng to _start:

_start:

bl init_io

bl init_spi1

bl configure_matrix

bl init_tc

bl init_adc1

bl init_dma2

bl start_adc1

bl init_snake

bl init_rng

Placing the food

To place the food we will generate two random numbers and treat them as column, row indexes. When we have the two numbers generated we need to check whether the food position that was generated lies in the snake. If it is inside the snake we will keep generating new positions until we generate one that is not inside the snake. When we have a valid food position we store it in FOOD_POS.

place_food:

push { r1, r2, r3, r4, r5, r6, lr }

generate_food_position:

// Generate column

bl fetch_random_number

// The RNG gives us a 32bit random number we only want a 3bit number

// Get 3 MS-bits

mov r2, r1, lsr 29

// Add one because columns start from 0x100

add r2, #1

// Shift to column position

mov r2, r2, lsl 8

// Generate row

bl fetch_random_number

// The RNG gives us a 32bit random number we only want a 3bit number

// Get 3 MS-bits

mov r3, r1, lsr 29

mov r4, #1

lsl r4, r3

// Create position in r2

orr r2, r2, r4

b check_food_in_snake

// Store the new position in FOOD_POS

spawn_food:

ldr r5, =FOOD_POS

strh r2, [r5]

pop { r1, r2, r3, r4, r5, r6, pc }

// Pass in food position through r2

check_food_in_snake:

ldr r5, =SNAKE_POS

ldr r4, =SNAKE_LENGTH

ldrb r4, [r4]

check_food_in_snake_loop:

ldrh r3, [r5], #2

cmp r3, r2

beq generate_food_position

sub r4, #1

cmp r4, #0

bne check_food_in_snake_loop

b spawn_food

// returns random number in r1

fetch_random_number:

push {r5, r6, lr}

ldr r5, =RNG_BASE

check_rng_ready:

ldr r6, [r5, #RNG_SR]

tst r6, #1

beq check_rng_ready

ldr r1, [r5, #RNG_DR]

pop {r5, r6, pc}

Now we will place an initial food in _start:

_start:

bl init_io

bl init_spi1

bl configure_matrix

bl init_tc

bl init_adc1

bl init_dma2

bl start_adc1

bl init_snake

bl init_rng

bl place_food

If you now run this no food will show up because we never add FOOD_POS to PIXEL_DATA.

Change update_pixel_data:

At the end of update_pixel_data there is a comment: TODO: Draw food. We will overwrite our comment with the following code:

update_pixel_data:

...

// TODO: Draw food

/*

Because we will use the existing update_snake_pixels_loop to merge

FOOD_POS and PIXEL_DATA, we check if we have already been in this part of the code

(Store 1 into r6 the first time we are here. The next time there will be 1 in r6

and we can jump to end_update_pixel_data).

*/

cmp r6, #1

beq end_update_pixel_data

mov r6, #1

// TODO: Draw food

ldr r3, =FOOD_POS

/*

Store address of FOOD_POS + 2 into r4 to exit update_snake_pixels

after one iteration. (r3 and r4 get compared in exit_snake_pixels)

*/

mov r4, r3

add r4, #2

// Use existing function to merge FOOD_POS and PIXEL_DATA

b update_snake_pixels_loop

end_update_pixel_data:

...

Run make && make burn you should see a food pixel light up in a random position.

Eating food

Eating food means finding out if the head position == the food position. If this is true, we only need to increment SNAKE_LENGTH and then call place_food, to place a new food!

We will check if our head is at food position in the move_snake function we wrote before. If you remember, this is the function that shifts the snake in memory. So if we increment SNAKE_LENGTH before we start shifting the snake in memory, we will shift the snake by one more place, thereby making it longer.

Update move_snake to check if head is at FOOD_POS:

move_snake:

ldr r1, =FOOD_POS

ldrh r1, [r1]

cmp r0, r1

it eq

bleq eat_food

// The rest stays the same

...

Define eat_food:

eat_food:

push { r5, r6, lr }

ldr r5, =SNAKE_LENGTH

ldrb r6, [r5]

add r6, #1

strb r6, [r5]

bl place_food

pop { r5, r6, pc }

Run make && make burn, you should now be able to eat some food!

Death

Now our snake can eat, but as you get bigger and the game becomes harder you will notice our snake cannot collide with itself to end the game. We will implement colliding, so that after we collide, the game restarts automatically.

Detecting a collision

Anytime a collision occurs, it is going to be between the head and some other body part, so we need to compare the head position to every body part. We will implement this checking and subsequent game resetting in the move_snake_loop (the loop for shifting the snake in memory), as this will loop through the snake anyways, we can use this to avoid a separate loop.

Update your move_snake_loop to this:

move_snake_loop:

ldrh r2, [r4, r3]

// Reset the game if the new head pos is in it's body

cmp r2, r0

beq reset_game

add r3, #2

strh r2, [r4, r3]

subs r3, #4

cmp r3, #-2

bne move_snake_loop

strh r0, [r4]

reset_game:

// Reinitialize snake to 3 pixels

bl init_snake

// Replace food, in case it was placed where the snake is after init_snake

bl place_food

// Continue game

b game_loop

As always run make && make burn and if you collide with yourself you will be reincarnated!